Heavy Duty Permanent Steel Grating For Construction Building

Heavy Duty Permanent Steel Grating For Construction Building

No se pudo cargar la disponibilidad de retiro

Spray Booth press welded Galvanized Mentis Grating Large Metal steel Grates for floor

JH Steel Grating

Galvanizied serrated grating is carrying flat steel and bars according to certain spacing orthogonal combination,to be open-steel components fixed by welding or pressure lock. Crossbar general use through twisted square steel may also be round steel or flat steel.

Material is divided into carbon steel and stainless steel. Steel grating mainly used for steel structure platform plate, trench cover, ladders treads, ceiling and other buildings.

1. Specifications

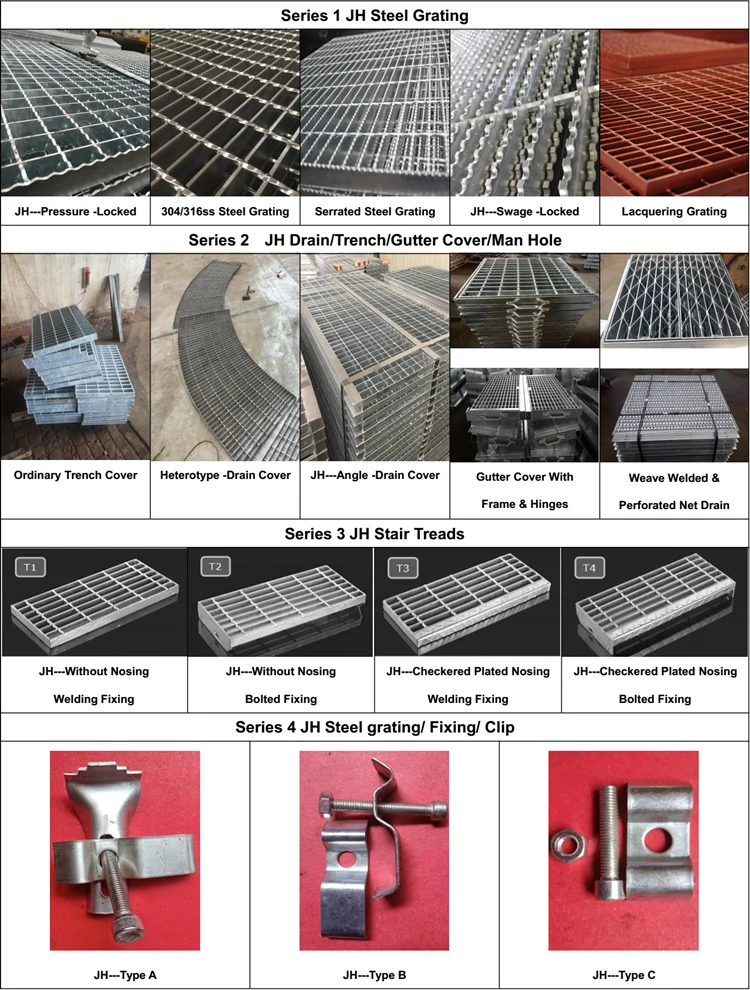

2. JH Steel Grating Series

There are 4 series of steel grating in JH Steel grating, drain cover, stair treads, steel grating clips.

We are able to provide a full range of steel grating series and accessories.

Spray Booth Galvanized Mentis Grating Large Metal Floor Grates

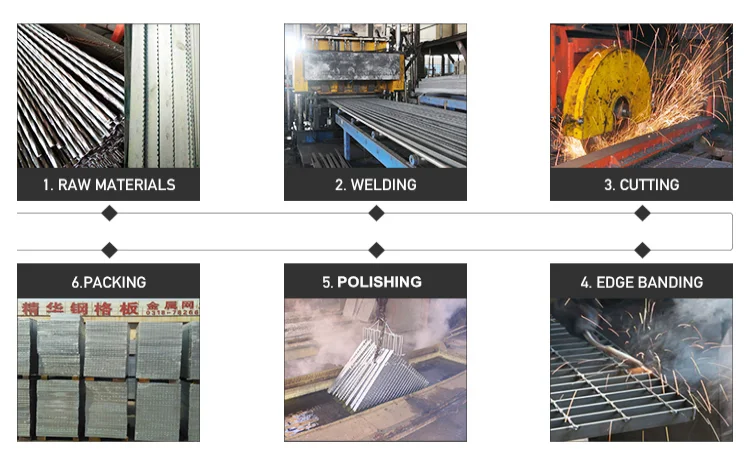

Production Flow

The production flow of Steel Grating is illustrated as the following .

| 1-Raw material | Cross bar/bearing bar |

| 2-Welding | Pressure weiding |

| 3-Cutting | Cut to target size |

| 4-Banding | Edge banding |

| 5-Surface treatment | Hot Dipped Galvanized |

| 6-Packing | Pack according to customer's requirement |

| 7-Loading | Professional Loading team to ensure the safety and integrity of the goods |

A. Production & packing

B. Loading

Safe and Economic packing & loading method.

From Metal–To Grating: JUST IN TIME

As a high performance grating manufacturer, JH Steel Grating works with the most modern production facilities, in sorted, serial manufacture and with intelligent planning and control soft-ware. Structure and production processes following the principles of lean management.

For the customer this means efficient organization, short turn-around times in grating production and total adherence to delivery deadlines.

Spray Booth Galvanized Mentis Grating Large Metal Floor Grates

Features

1.Hot-dip galvanizing: Rust strong, maintenance-free and replacement.

2.Best drainage: water leakage area of 83.3%, is more than double the cast iron.

3.Save investment: long-span. Heavy load than cast iron and the lowest savings in the cost of replacing stolen, then crushed.

4.High strength: strength and toughness is much higher than cast iron, can be used for port, airport and other large span and heavy load conditions.

5.Size Multi: different specifications can meet the different environments, load. Span, size and shape required.

Application

Steel grating is use of steel grid plate design and is widely used in city roads, squares, gardens, piers, airports, car parks, roads, railways, industrial engineering, civil construction of various industries.

Spray Booth press welded Galvanized Mentis Grating Large Metal steel Grates for floor

Share